Advanced inspections ensuring stability and safety of vertical infrastructure through high-resolution data capture and precise analysis.

Master Drilling Europe’s advanced shaft inspection services deliver high-resolution data to ensure the safety, reliability and ongoing performance of critical infrastructure. Utilising Hovermap technology, we provide efficient, comprehensive inspections, even in hazardous or hard-to-reach areas. Our solutions offer mining and geotechnical engineers crucial insights for effective decision-making, keeping both personnel and operations safe.

Mining environments are inherently high-risk, particularly when it comes to vertical infrastructure like orepasses and raises. Master Drilling Europe utilises advanced laser scanning technologies to map these vertical structures, providing mining and geotechnical engineers with a comprehensive understanding of the impact of mining-induced and tectonic stresses. This data is crucial in maintaining operational safety and efficiency. By accurately mapping these structures, we help identify existing vulnerabilities and support engineers in optimising infrastructure for future operations, ultimately reducing risks and improving productivity.

Helps assess mining-induced stresses effectively.

Reduces the need for personnel in hazardous areas.

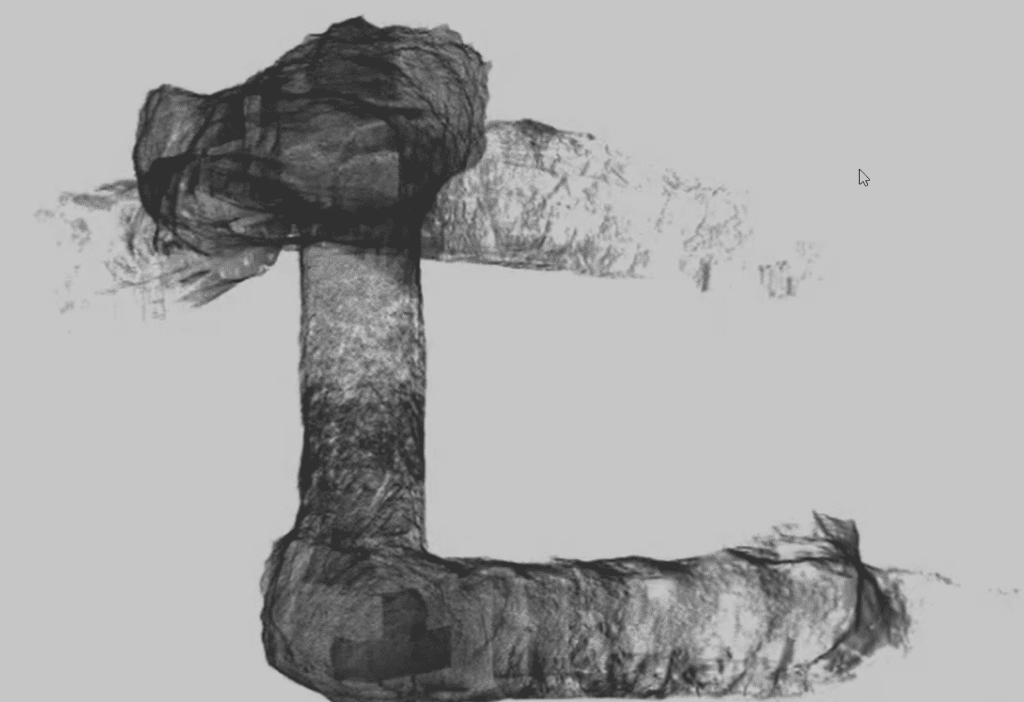

Hovermap is a versatile LiDAR scanning solution that Master Drilling Europe uses for data collection in challenging environments, particularly in inaccessible areas. Mounted on drones or lowered on a tether, Hovermap autonomously navigates underground voids, capturing high-resolution data while avoiding obstacles. This autonomous capability significantly reduces the risks faced by personnel and the time required to inspect difficult-to-reach areas. The resulting data offers clear, shadowless visualisations, which allow for a better understanding of the state of underground infrastructure and help in the timely identification of issues.

Capable of navigating hazardous areas without GPS.

Suitable for both autonomous flight and tethered inspections.

Hovermap minimises personnel exposure to dangerous environments like confined spaces, elevated locations and unstable edges. Its beyond line-of-sight capabilities ensure safety while collecting vital data for smarter decision-making.

Quickly map difficult-to-access areas with Hovermap’s versatility. Fly, drive, walk or tether the system to gather precise data on your schedule, all with minimal disruption to ongoing operations.

Gain comprehensive views with Hovermap’s high-resolution point cloud data. This accuracy enhances modeling and analysis, giving stakeholders a deeper understanding to guide project outcomes.

With minimal training, operators can complete a full Hovermap mission, from take-off to landing, using just a tablet. Hours of survey work can now be condensed into mere minutes, saving valuable resources.

Master Drilling Europe uses several deployment methods to ensure efficient data capture for vertical structures. Hovermap can be flown autonomously in areas with sufficient width, providing fast and high-quality scans. For narrower passages, the system can be attached to a hoist, protective cage, or motorised buggy. These methods ensure reliable data collection across different vertical structures, including orepasses and vent rises, supporting everything from condition assessments to structural integrity checks, while allowing rapid deployment to meet the varied demands of projects.

Includes drone-mounting and hoist attachment.

Rapidly captures detailed data for analysis.

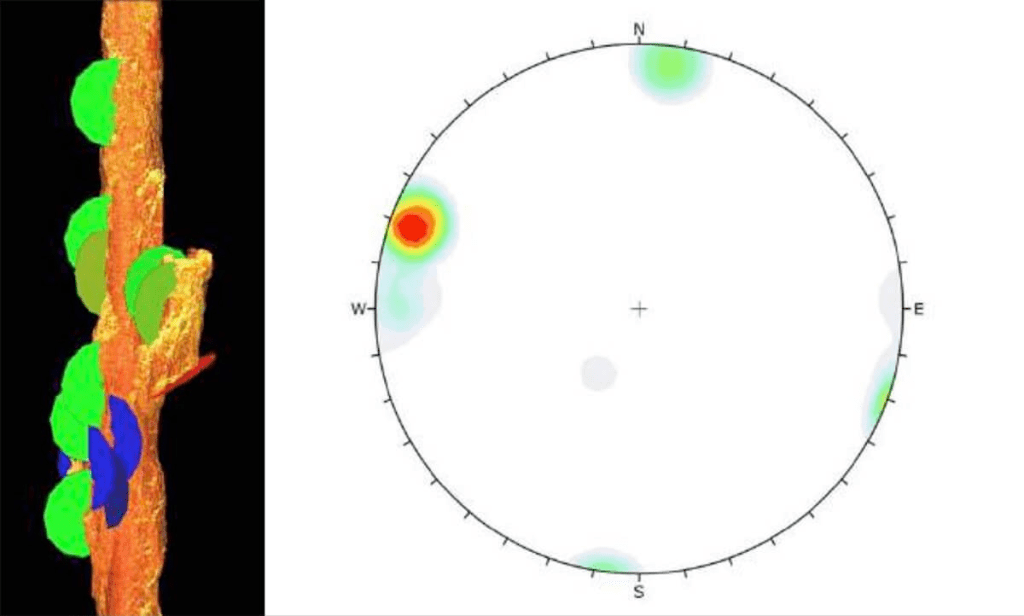

Understanding potential failure mechanisms in underground mining is critical for maintaining safety and operational efficiency. Master Drilling Europe uses Hovermap to identify structural issues like stress-induced spalling and buckling in orepasses and raises. These detailed analyses provide visual data on stress-related failures, helping to understand rock mass responses. This information is used to inform proactive adjustments in future designs, reducing the risk of failure and enabling engineers to address weaknesses before they become critical, thereby ensuring long-term stability.

Visualises stress-induced and structural failures.

Informs adjustments to future designs to mitigate risks.

We use Hovermap to detect stress-induced and structural failures, providing clear visual data for accurate understanding.

By understanding failure mechanisms, we inform adjustments to future designs, reducing risk and ensuring stable mining structures.

Visual data offers insights that guide proactive measures, improving the stability of mining operations.

Our methods help address weaknesses before they become critical, ensuring safety and longevity of underground structures.

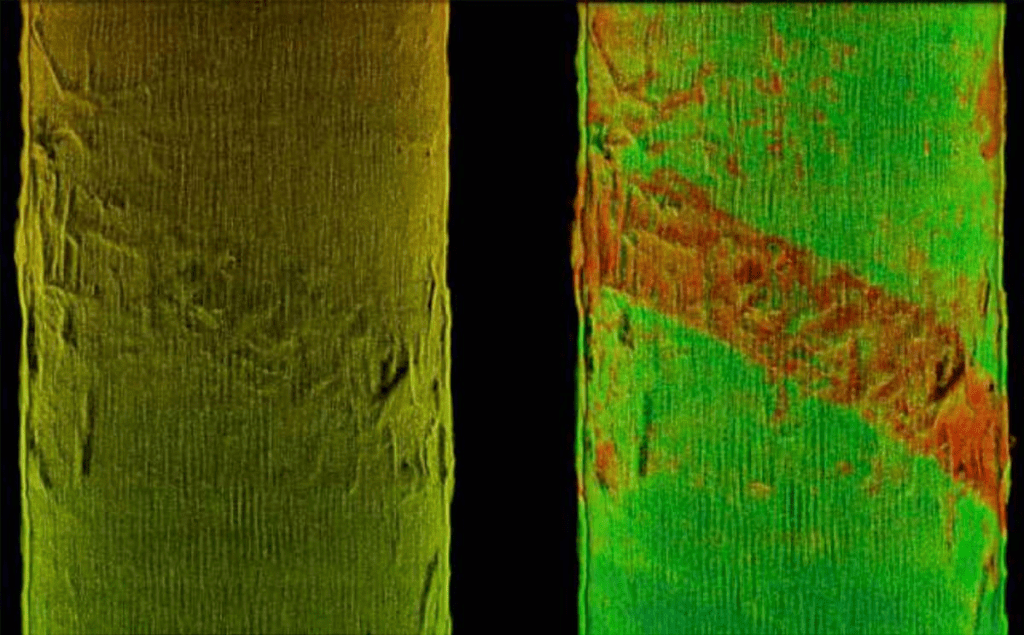

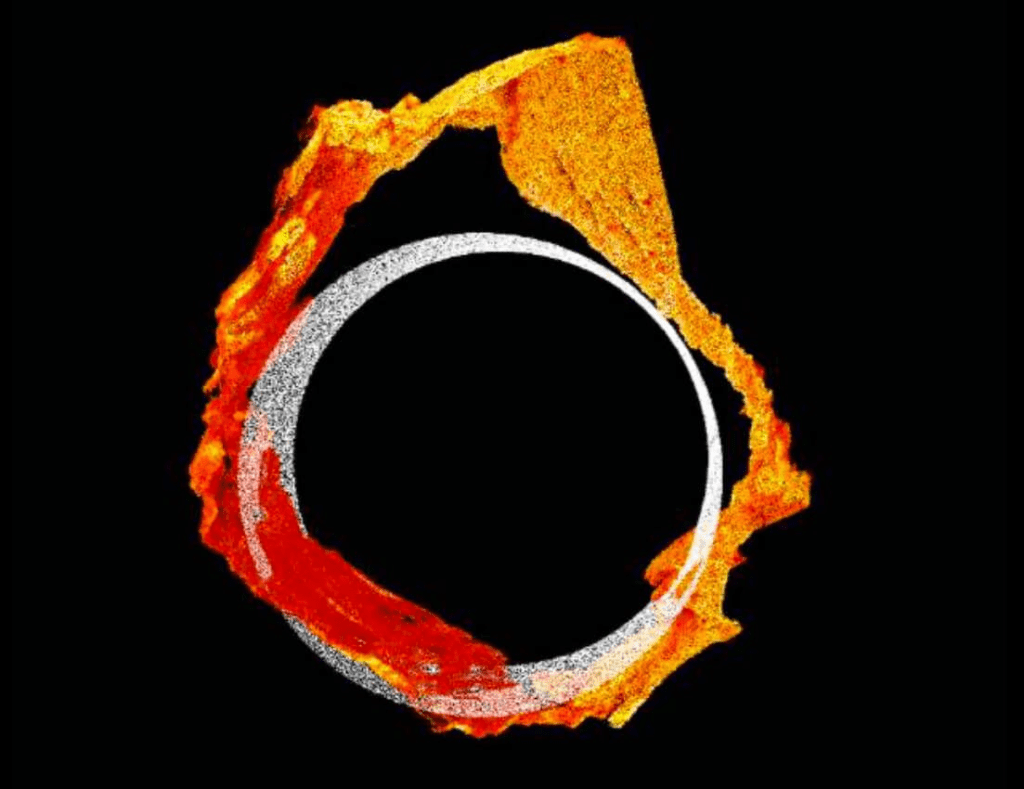

Master Drilling Europe’s condition inspections involve using Hovermap’s LiDAR data to monitor the health of vertical structures. High-resolution point cloud data reveals geological features and tracks changes in the condition of orepasses, identifying any wear or deterioration that could impact their performance. By conducting regular scans, we help clients monitor the rate of change and assess when maintenance is required. This helps in planning the lifespan of infrastructure components, determining when repairs or replacements are needed and preventing unexpected failures that could lead to costly downtimes.

Track changes over time for effective maintenance.

Supports planning to extend the lifespan of infrastructure.

Raise bore performance assessments provide a comparison between as-built shafts and their original design. Master Drilling Europe conducts detailed raise scans immediately after reaming, capturing data that highlights deviations from design specifications. This information is used to validate geotechnical conditions and track any damage. The insights gained help refine future designs, improve stability forecasting and ensure that infrastructure meets stringent safety requirements. These comprehensive analyses are key to delivering optimised and safe raise bore solutions in line with project specifications.

Compare scanned data with original design.

Ensure shafts meet engineering standards.

Our experts are ready to discuss how Master Drilling Europe delivers efficiency and precision to your drilling needs—reach out today.

Master Drilling Europe: Regional knowledge, global strength, delivering precision drilling solutions across Europe.

Contact

Office

Strandgatan 22

931 31, Skellefteå

Sweden

Workshop

Boliden Industrial Area

936 32, Boliden

Sweden