Master Drilling Europe offers an extensive range of drilling solutions to meet the complex needs of the mining, energy and infrastructure sectors across Europe.

Our services are specifically designed to address the diverse challenges found in European projects. From creating efficient hydroelectric tunnels to developing robust mining infrastructure, we combine regional expertise with cutting-edge global technologies to ensure each project is executed with precision, safety and efficiency.

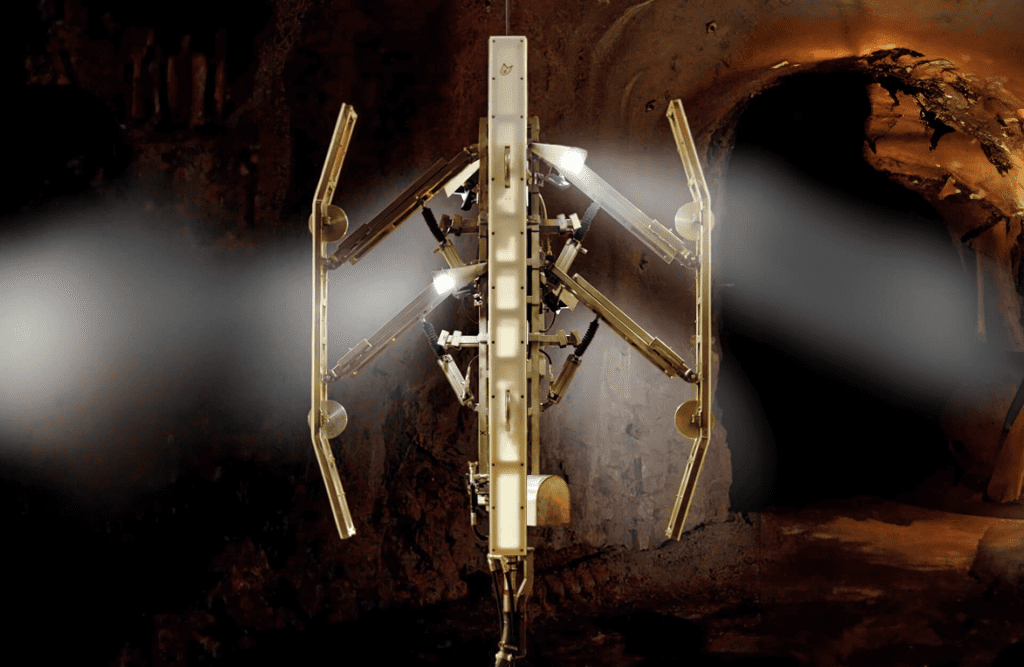

Our Shaft Support service plays a crucial role in ensuring the stability and longevity of underground structures. Using our Shaft Support Robot, we remotely apply shotcrete to secure the walls of shafts. This process significantly reduces the risk to personnel by minimising their exposure to potentially hazardous conditions underground. The use of Lidar scanning technology for pre- and post-operation assessments ensures precise, consistent application, optimising structural safety and quality.

Raise Boring is a core capability of Master Drilling Europe, enabling us to create large-diameter shafts between different levels of a mine or infrastructure project with minimal surface disruption. It is a safer and more efficient alternative to traditional shaft sinking methods, as it eliminates the need for personnel to be in potentially hazardous zones during the drilling process. This method is widely used across mining operations, providing crucial infrastructure for ventilation, hoisting and ore transport. Our flexible range of diameters and depth capabilities allows us to handle projects of varying complexity, from large-scale mining developments to niche applications in energy and civil sectors.

Horizontal Raise Boring is an innovative service that allows for the creation of stable and precise tunnels horizontally or on an incline. This method is particularly suited to energy and utility projects, including hydroelectric power generation and urban utility conduits. Unlike conventional tunnel excavation methods, Horizontal Raise Boring is cost-effective and significantly reduces surface disruption, making it ideal for use in densely populated urban environments or environmentally sensitive areas. By using this technology, Master Drilling Europe contributes to the efficient development of critical infrastructure, with a focus on minimizing environmental impact.

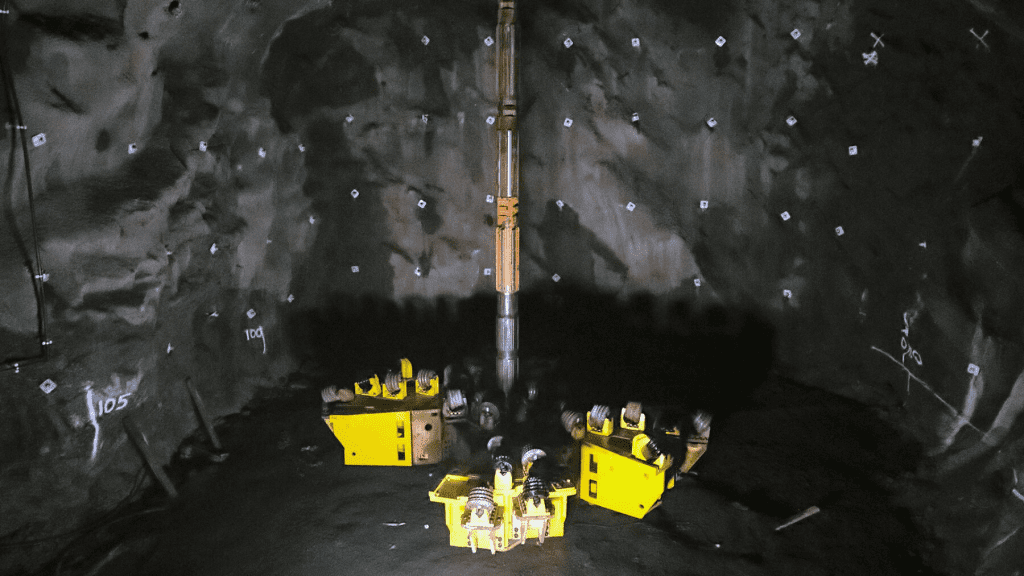

Box Hole Boring provides an effective way to drill upwards from an underground level, creating essential pathways for ventilation or ore transportation. This bottom-up approach is particularly useful in mining operations where space is limited or where it is impractical to create a shaft from the surface down. Box Hole Boring is designed to be a safer alternative to traditional methods, keeping personnel out of the excavation zone and relying instead on advanced boring machinery to perform the job. This technology allows us to create effective material handling solutions and enhances the overall efficiency of underground mining systems.

Master Drilling Europe’s Tunnel Boring solutions are designed for challenging underground construction projects in both the mining and civil infrastructure sectors. Our Mobile Tunnel Borer (MTB) is specifically engineered for hard rock environments, allowing for the efficient creation of tunnels at various inclines. This service supports a range of applications, from mining access tunnels to urban infrastructure, including metro and utility tunnels. The MTB’s compact and modular design ensures it can operate in confined spaces and be easily dismantled and transported after the project is completed, ensuring minimal disruption to ongoing operations. The high-level automation involved provides a smooth, consistent excavation process, reducing the time and cost associated with conventional methods.

Blind Shaft Boring is an efficient method for creating vertical shafts without requiring lower-level access, making it ideal for new mine developments and infrastructure projects. This technology allows for the safe and controlled excavation of shafts up to significant depths, even in challenging conditions. By using Blind Shaft Boring, Master Drilling Europe can offer solutions for constructing ventilation shafts and access routes where conventional methods would be impractical or unsafe. This technology ensures a consistent and safe excavation process, significantly reducing the need for personnel to enter potentially hazardous zones during shaft construction.

Our Shaft Inspection services provide a thorough assessment of shaft safety and integrity, ensuring all structures meet industry standards and regulatory requirements. Using advanced Lidar scanning and other technologies, we deliver detailed insights that allow for proactive maintenance planning. This service helps extend the lifespan of shafts, reduces the risk of unexpected failures and ensures the safety of ongoing operations. By identifying issues early, we help clients avoid costly repairs and operational downtime, keeping projects on track and infrastructure safe.

Our experts are ready to discuss how Master Drilling Europe delivers efficiency and precision to your drilling needs—reach out today.

Master Drilling Europe: Regional knowledge, global strength, delivering precision drilling solutions across Europe.

Contact

Office

Strandgatan 22

931 31, Skellefteå

Sweden

Workshop

Boliden Industrial Area

936 32, Boliden

Sweden